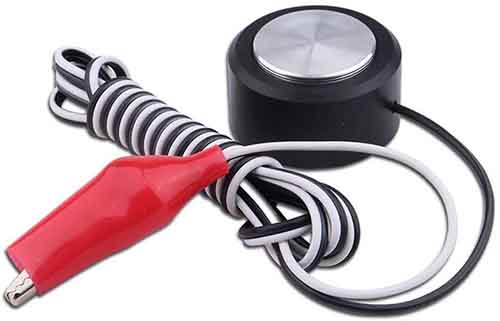

I left enough adjustment room to get the camera to hang vertically, but having added that adjustment the camera now will swing like a pendulum with any breeze or slight bump. First, the balance point was closer to the inside than I expected. Putting it all together and adding a photo camera reveals two mistaken assumptions I made. I was inspired by how the touch plate for my CNC Shark connects. I drilled a 5/32" hole in my plate and used a speaker plug inserted into it to connect from the battery. You'll need a way to hook one wire from the battery case/LED to the plate, then solder the other wire to the alligator clip. If you don't have or want to buy the puck I linked to, then any small chunk of conductive metal and an alligator clip lead can be used. The photos here show a simple bar of aluminum used for the touch plate, The numbers on the battery box remind me how thick the plate is. I had the CNC mill a flat plane across the plastic bottom of the puck to make it uniformly thick. then press fit my puck upside down in that level (to the CNC) hole. I had my CNC mill a hole to tightly fit the metal disk. The only problem to this point was that my touch puck wasn't consistently thick. The led is easy to see from back at the keyboard/PC station and makes it easy for one person working alone to handle setting Z. The LED that glows on contact will be more accurate than using paper was. This solution isn't as automated as it could be if the touch plate was wired into my CNC controller, but so far I haven't found any info on how to go about that. I enter that value when touching off Z in LinuxCNC. Now I step until the LED glows again, and I know I'm within.001" of the top of my material. I jog the bit to within 1/8" or so of the disk, then set my step increment to. To use I clip to the router bit and place the plate underneath it atop the material I'll be cutting. Now the LED glows when the plate and alligators touch. I drilled a 5mm hole in the battery case for the LED, then wired the LED in line with the batteries and contacts. I went to my local Radio Shack (which sadly has now closed down thanks to internet competition) and picked up a battery case, 3v green LED bulbs, and some AAA batteries to go with the unused touch puck and alligator clip ( Link) I've had for awhile. That idea intrigued me so much I knew I had to make my own version. 005 using this process.Ī User Forum member KLWestfall posted his idea of using a light bulb, thin metal plate, and an alligator clip to signal when Z has touched down. Set Z at 0 there then lift up to remove the paper. I put the paper under the bit, then slowly (.005") step it down until the paper is trapped. I've been using a piece of paper to set my Z axis origin height. No touch off plate came with or is available for my CNC (yet).

0 kommentar(er)

0 kommentar(er)